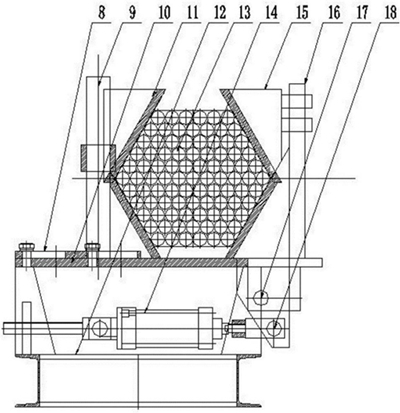

At present, an independent and complete steel pipe packaging machine system with independent products has been formed in the United States, Japan, Germany and Italy, for example, the Cimat steel pipe packaging machine in Germany. The overall mechanical structure includes a stepping pipe moving mechanism, a horizontal pipe moving mechanism and a hexagonal forming mechanism, and its mechanical transmission is driven by a chain. This kind of supporting chain conveying device has the advantages of large carrying capacity, certain cushioning and anti vibration performance, high transmission efficiency, large transport capacity, etc., but at the same time it has disadvantages of heavy dead-weight, complex structure, certain noise, high maintenance costs of chain wear and not being suitable for site changes.

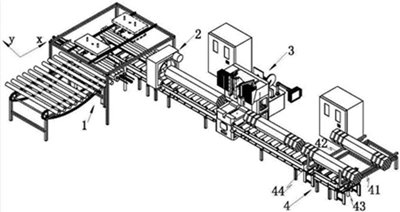

Pipe automatic packaging production lines

The automatic steel pipe packaging machine is used in many factories, and its main function is to package the pipe products. The automatic packaging machine is roughly divided into two types, one is the steel pipe automatic packaging machine, and the other is the ordinary packaging machine. Then, what is the difference between the steel pipe automatic packaging machine and the ordinary packaging machine?

The automatic steel pipe packaging machine is a special machine for steel pipe bundling and packaging, which is different from other ordinary bundling equipment. Because the steel pipe bundle has the characteristics of heavy weights (The national standard is 5 tons for each bundle.) and long length (The national standard is from 6 to 15 meters.), the steel pipe packaging machine must meet the requirements for good strength of bundling materials, great bundling force, firm and reliable bundling.

After decades of technical accumulation and continuous development, foreign steel material packaging machines have multi varieties, specialization and serialized production. The degree of automation has been continuously improved; the bundling speed has been accelerating, and the reliability and service life have also been continuously improved. Internationally well-known steel packaging machine manufacturers mainly include American SIGNODE company, Sweden SUND BIRSTA company, Germany TITAN company, etc.

However, most of the packaging machines manufactured in China are used for manual, semi-automatic and fully automatic packaging for light and service industries, and they are packaging machines with general purposes. There is still a great demand for the production of high end and high efficient automatic steel packaging machines such as the automatic packaging machine using steel belts, and the demand for steel metallurgical product packaging can not be met.

1. Working principles

The working principle of the steel pipe automatic packaging machine is different from that of the ordinary packaging machine, because one requires manual operation by personnel, and the other does not. Therefore, it is precisely because of this difference, steel pipe automatic packaging machines will be chosen in many factories.

3. Prices

Because the principle and work efficiency are different, the price between the two is also very different. Therefore, consumers must also consider the price factor when buying.

4. Service lives

The service life of the steel pipe automatic packaging machine is longer than that of the ordinary packaging machine, because it does not require too much operation when it is working. Therefore, the probability of failure is relatively small. The steel pipe automatic packing machine can realize automatic packaging, and its function is to make the plastic belt cling to the surface of the bundled package and to ensure that the package is not scattered due to improper packaging during transportation and storage. At the same time, make the bundle neat and beautiful. The steel pipe automatic packaging machine is now widely used, not only because it is convenient, but has outstanding structural design too, which make more people use it.

Generally speaking, structural characteristics of the automatic packaging machine mainly include the following four aspects:

1. Instant heating and immediate packaging

2. Integrated circuit design

3. Automatic shutdown devices being power saving and practical

4. New brake design

Next: An Overview of Seal Failures of Flanges (Part One)

Previous: Alloy Steel Pipes